Concrete Brick Making Machine Morbi India

Concrete block machines are extensively utilized by novice and small-scale business owners. A new business owner aims to balance cost efficiency and productivity. This is possible by using the latest models of concrete block-making machines. Modern models can be put in small spaces, and it is possible to start an enterprise of a smaller scale with limited resources concrete brick making machine morbi india.

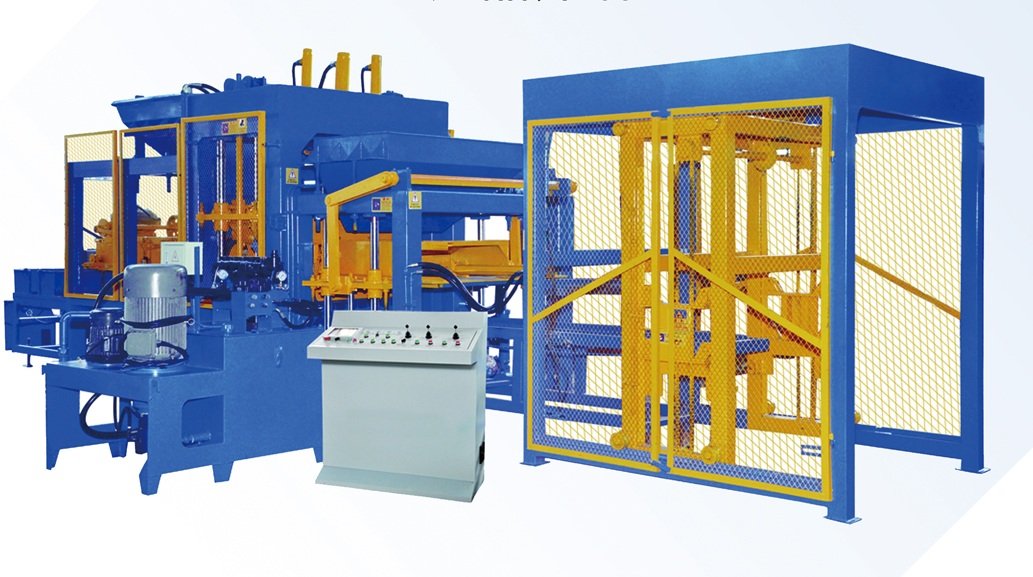

You can achieve higher quality control with this concrete brick making machine price in india,. There is less work required, and you increase production. Various products can be made by the same machine using the ease of mold replacement, which keeps costs down and prices competitive. Various kinds of block-making machines have different production capacities. St stationary concrete block-making equipment must be set up on a solid concrete foundation. This machine utilizes pallets to create concrete products.

Concrete block-making machines utilize PLC Control Systems and cement, concrete, and fly ash as the raw ingredients to produce high-quality blocks that are produced automatically. The blocks are used for various uses, like roads and construction projects. concrete brick making machine in india, are constructed to serve specific needs. The machine can handle each of the four phases of the concrete block-making procedure completely. This involves the batching process and mixing of components,

Paver block machines made of concrete are made in various capacities and at various levels of automation concrete brick making machine. The main feature that differentiates the paver block machines is that they come with two buckets. It produces an elongated paver that has an attractive design. Paver block machines can be found with automated systems. Paver block-making machines are equipped with specific vibration systems to create high-quality, durable concrete products fully automatic concrete brick making machine.

concrete brick making machine manufacturers are extraordinarily sought-after and are extensively employed in construction projects across the US due to their numerous advantages, like durability and strength and the stability of their structure and insulation, resistance to fire, and sound absorption. Concrete blocks are of an appealing shape and are easily accessible for all styles of architectural design. It is believed that the Indian industry of concrete blocks is driven by the growing interest in rehabilitating the existing infrastructure and the increasing investments in residential buildings. The growth of sustainable construction materials is anticipated to boost the market’s growth even more.

Concrete Brick Making Machine Price In India

There is a variety of automatic brick making equipment on the market; however, they are accessible and purchased by large-scale industries. In the case of small-scale enterprises brick manufacturing, available machines typically focus on one particular element like cost and production rates, algorithms and type of bricks to be produced, the machine’s weight, etc. If the rate of production of a specific machine increases, the price, weight, and complexity of the algorithms concrete brick making machine.

It allows the motor to initiate the centrifugal pump connected to the motor. The centrifugal pump produces vacuum pressure to draw the oil out of the concrete brick making machine price in india. The oil is then transferred to the manifold block via the hose pipes. The pressure needed to pressurize the block can be set by the pressure control valve that can be monitored using the gauge for pressure. The valve for pressure control and the gauge for pressure is plugged in between the centrifugal pump and the manifold block. The oil circulates in the manifold block.

That is controlled via the solenoid valve concrete brick making machine in india to the hydraulic, which is directed by the solenoid valve to the hydraulic cylinder.

The oil pressurized into the cylindrical pushes the piston up to compress the material in the mold. When the brick is formed, the movable plate described above is moved back to its initial location, fully automatic concrete brick making machine, can be opened at the bottom. The piston goes up to take it out from the mold. Then, the movable plates will push the brick on toward the conveyor. After the brick has been pushed onto the conveyor, the piston shifts downwards, using pressurized oil. Meanwhile the movable plate concrete brick making machine manufacturers

The mold is opened by lifting it from the top, allowing the making of a new brick. The procedure continues until the number of bricks is met concrete brick making machine manufacturers morbi india.

The intelligent and integrated brick-making machine was created to offer an affordable production rate with the cost of an investment. It’s an automated machine that uses an efficient algorithm concrete brick making machine morbi ndia. It is a multi-purpose device that is capable of producing different types of bricks that are high-quality simply by replacing the mold. The machine’s cost is about 40-44 thousand 6 hundred fifty. The machine was designed to accomplish the job in a short time. It can be used to produce large quantities,

This improves the efficiency of the plant, which reduces the load and also reduces production costs.

Brick is a vital requirement for building and is the primary source of income for many people in India. Child labor is one of the significant issues, and surprisingly, they are the most employed in the brick manufacturing industry. It can decrease child labor by making bricks using automated technology the machine. These machines can increase the rate of production.

The size of an enterprise will increase. An enterprise’s future will be when there is plenty of demand for various kinds of bricks manufactured through automated brick-making machines. These are the suggestions.

Concrete brick equipment in india

The water source and type utilized were based on the site’s location. Some sites employed wells drilled and supplied by water bowsers, while others utilized tap water. Water was never tested before it was used in the production of blocks. Most of the locations in Goba utilized drilled wells and water bowser delivery because of the scarcity of tap water in the region.

The strength of bricks is contingent on the ability to achieve incipient fusion and partial vitrification in firing. Since compressive strength and absorption values are also dependent on the firing temperature, these parameters, together with the saturation coefficients, are considered to be indicators of the brick’s durability in specifications for brick. However, due to different raw materials and manufacturing processes, the single number of values for absorption and compressive strength will not be able to determine the extent of firing accurately.

Its color is contingent on its chemical composition, the temperature of firing, and the method used to control the firing of all the oxides found in clays, the one that has the most impact on the color. No matter its natural color, clay with iron in every form will show a red hue in the presence of an oxidizing flame due to iron oxide’s formation.

In an atmosphere that is reducing in a reducing atmosphere, the same clay will take on a black (or black) shade. Creating a reducing atmosphere within the kiln process is known as reduction firing or flashing. With the same raw materials and manufacturing process and process, darker shades are linked to more excellent firing rates.

Temperatures are higher, with lower absorption values and stronger compressive strengths. But for products made from various substances, there isn’t any link to color, strength, absorption, or color concrete brick making machine price in india.

This brick machine, as the name suggests, is designed to make various types of concrete bricks. Either hollow brick or solid brick, both can be produced. It does not need to go through sintering or drying and other troublesome processes, but can be made directly by squeeze condensation. The required production time is very short, you can take advantage of fast shipping. Often a brick machine needs only one month to successfully recover costs and achieve profitability.

Some ash, stones or abandoned slag and other products will be made into cement bricks. It can be said to be a way of turning waste into treasure, and these useless materials can play a very powerful role. Compared to some bricks with high production material requirements, the production cost of cement bricks is high. And we can see that the cement bricks produced in this way, although the price is low, but the effect of use is not inferior to that of ordinary red bricks. And it also has more advantages than red brick in hardness, strength etc.

Nowadays brick machines can produce more and more brick products. We can see that it produces standard bricks, hollow bricks, lightweight bricks and pavement bricks and other products, and these bricks are now available in the market which are very rich in applications. Due to the consumption of cement bricks especially the production of bricks is low and the price of cement bricks is also low, the sum of the two increases the market prices of these bricks. So the brick machine became the first choice when using different concrete brick making machine in india, effectively allowing more concrete blocks to be used in the market and bringing great improvements.

KIRTI MACHINE TOOLS

Satwara Estate, Panchasar Road, Morbi – 363641 ( Gujarat ) India

+91 9601008800, +918866320614

info@kirtimachinetools.com

Contact Us

Copyright © 2022 Kirti Machine Tools. All Rights Reserved.