Cement Brick Making Machine Morbi India

The machines are quick and efficient. Both serve their purposes effectively. Concrete Block Making Machine and cement brick making machine morbi india demonstrate superior to their counterparts. Let’s take a look at why concrete blocks differ from bricks. Concrete Blocks are bigger and have an enlargement of joints. This improves the consistency, precision and strength of the construction. Concrete Blocks offer higher thermal insulation and greater durability to the structure. Concrete Blocks can speed up construction and decrease the total cost. Improved water protection and better Acoustic insulation are other benefits of block machines.

It is the smallest and the most affordable brick-making machine. It is most of the work has to be completed by hand. This means that it will require more employees as compared to other machinery. In this method, the mortar is made by hand. Then the mortar is transferred into the machinery, and dry bricks are removed by hand. This method has the benefit of not needing pellets to make bricks. Bricks are laid on the surface using the equipment cement brick making machine manufacturers morbi india.

cement brick making machine price in india is a crucial element that is used in construction. It is a simple way to create bricks made from clay or shale that can be used for construction. There is a variety of brick-making equipment which can make it difficult to determine the best one for your business. A brickmaker should be user-friendly, produce high-quality bricks, and be strong enough to stand up to the damage associated with frequent usage.

fully automatic cement brick making machine morbi india have been around for quite a long time. However, they ought to be better known. They can assist you to reduce time and costs and help your construction projects run smoothly. Although the price is an important factor when comparing various brick Making Machine prices available on the internet, other elements may also be crucial. Other variables include the size, cycle moulding time in pcs/hour, type of brick and power, automated grade, certification, delivery charges capacities, and so on. Before buying a machine, ensure that you read the exact specifications.

Humans are more efficient than machines. The machine utilizes the power of hydraulic pressure and vibration-based feed methods to create each brick with incredible precision and accuracy. There are now fully automated brick machines that can automatize the entire process, starting with raw material mixing and ending with brick production fully automatic cement brick making machine manufacturers. A pallet stacker built into the machine is used to organize the bricks, making the process of making bricks simple, fast, quick, and precise.

Cement Brick-Making Machine Manufacturers Morbi India

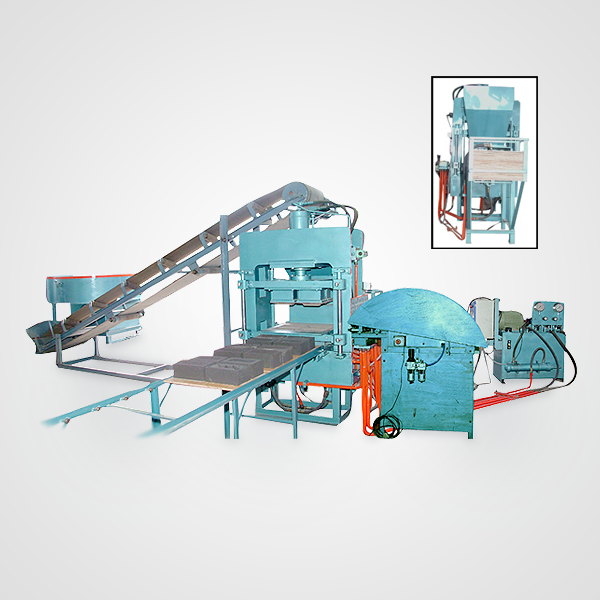

The machine for making cement bricks uses a variety of low-cost substances to create pavement slabs, cement bricks, and so on. These include fly ash and sand waste leftovers and waste stone powder construction waste, and more. cement brick making machine morbi india Every brick made of cement has to be fitted with the appropriate moulds. Compression moulding technology to make concrete bricks, pavements, and cement blocks offer advantages due to its high quality and durability. The road slabs and the cement bricks are made specifically to build sidewalks on each side of an expressway and have high coordination. So long as road construction is not separated from road slabs and the cement bricks will be ensured.

The cement brick manufacturing machine manufactured by our factory can press different designs of pavement bricks, clay bricks for slope protection and so on. Add pigments. The machine can also make different colours of vibrant pavement bricks. This cement brick-making utilizes hydraulic transmission, integrated oil circuits and electrical control. It is distinguished by its high automation, low noise, longevity of service, ease of operation and compact design cement brick making machine manufacturers morbi india.

The machine is constructed and installed using the ability to move the beam. The force is uniform, the mould cover is difficult to rotate, and the placement is precise and reliable. The machine can perform automatic return, stop, and other functions cement brick making machine price in india. The machine for making cement bricks ensures that the product is consistent in size and weight. Adopt a heavy-duty structure design. Make use of high-strength, high-strength stainless steel with special welding technology. It will assure that the body has excellent rigidity and self-weight and is not resonant when interacting with an excitation mechanism. The life expectancy of cement brick-making machines.

The design of the block is different in line with the needs of the construction. Modern brick-making machines include advanced control systems that allow you to modify the moulding design according to the requirements. Making the switch between semi-automatic and fully automated is also an option with these machines. The efficient hydraulic pressure systems and intricate feeding systems create each piece with extreme precision and precision. They also offer a closed-grain structure to the block, making it extremely rigid, vibration resistant, and strong fully automatic cement brick making machine morbi india.

Cement Brick-Making Machine Price In India

fully automatic cement brick making machine manufacturers can be constructed from fly ash, slag gauge, and other industrial waste. This can be used to recycle industrial waste, ultimately improving environmental conditions. Modern machines are developed to reduce as much as 40% of energy consumption. This can reduce costs and profit overall. The quick and efficient machine production process also reduces the block’s cost per unit.

They require no power to run. Everything is done by hand, the maintenance costs are minimal, and very little or no knowledge will be required to operate the device. Additionally, manually operated brick-making machines are more affordable than other types of brick-making equipment. There are some disadvantages of this kind of brick-making machine, such as the production rate being slower than those with cement brick making machine,. The operator will is exhausted quickly due to working continuously since the system demands an enormous amount of physical power, and the absence of the control systems and the bricks that are made need uniformity.

The study examined the compressive strength and elastic properties of wire-cut table-moulded bricks from India with various mortar grades. The various combinations of prisms for masonry and wallets, such as soft brick-strong mortar and strong brick-soft mortar, were utilized for the experiment. In order to investigate the impact of size, various sizes of wallets and prisms with different bonding arrangements were tested. A mathematical relationship between the compressive strength of masonry prisms and the strength of mortar and brick was discovered in an Indian context.

KIRTI MACHINE TOOLS

Satwara Estate, Panchasar Road, Morbi – 363641 ( Gujarat ) India

+91 9601008800, +918866320614

info@kirtimachinetools.com

Contact Us

Copyright © 2022 Kirti Machine Tools. All Rights Reserved.